Promoting DX by linking design and manufacturing, contributing to improved economic productivity and diverse working styles

News Facts:

– Fujitsu Manufacturing Industry Solution COLMINA Digital Production Preparation VPS enhanced with new 3D BOP (Bill of Process) creation function, visualizing production processes to support users, reduce errors in manufacturing, and centralizing data of common tasks to minimize the need to redo tasks.

– Supporting adoption of new working styles in the “new normal” era by bringing about the convergence of real world manufacturing and digital world while contributing to improved productivity, quality, and faster delivery of new products to market.

Fujitsu today announced the launch of a new version of the Fujitsu Manufacturing Industry Solution COLMINA Digital Production Preparation VPS (1), a series of tools developed by Digital Process Ltd. to support the digital transformation (DX) of production preparation tasks in manufacturing. Sales will commence for the Japanese market today, June 30, with availability in international regions at a later date.

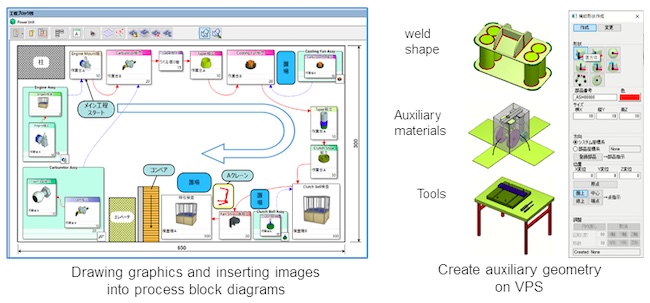

The latest version offers enhanced functions, including a feature that allows users to create a 3D bill of process (3D-BOP) (2) that links 3D data to production process information for production preparation activities such as manufacturing prototyping and process planning. Specifically, the new version includes an improved function for visualizing machine layout and work procedures in a process block diagram (3) in an easy-to-understand manner illustrated with graphics and image inserts, as well as an enhanced function to centralize work data for parts with common specifications in manufacturing lines that handle products with multiple specifications. This makes it possible to quickly create a highly accurate 3D-BOP that can reduce manufacturing errors and the need to redo common tasks. With this tool, Fujitsu can bring the real world of manufacturing closer to the digital world, helping to deliver products to market faster and improve overall productivity and quality.

Fujitsu’s VPS offering will accelerate DX in the manufacturing space by linking digital data from design to manufacturing sites and supports working styles at manufacturing sites for the “new normal,” streamlining work processes and promoting the ability to manage operations remotely. Fujitsu will also contribute to the achievement of the SDGs (Sustainable Development Goals) by improving productivity and quality and creating innovations from a variety of perspectives.

Background

The SDGs Action Plan 2021 (4) announced by the Japanese government in December 2020, identifies the promotion of digital transformation, and establishment of a system where everyone can benefit from digitization, and work to establish and accelerate the ‘new normal’ as a priority issue. At manufacturing sites, DX is expected to link the entire process from design to manufacturing with digital data, and to improve efficiency and productivity by centralizing data, contributing to the fulfillment of this objective.

In the manufacturing industry, COVID-19 is causing demand for new ways of working at manufacturing sites. Simultaneously, it is becoming increasingly difficult for manufacturers to direct assembly operations, which have been conducted at overseas plants. These factors have led to a growing demand for 3D-BOP solutions that can effectively visualize manufacturing sites.

To address this need, Fujitsu has launched a new version of its VPS with enhanced functions for creating a visually appealing 3D-BOPs and streamlining operations on manufacturing lines.

Features of the New Version

1. VPS Standard and VPS Manufacturing, 3D-BOP creation tools that more faithfully represent the manufacturing site

VPS Standard and VPS Manufacturing are 3D-BOP creation tools for reviewing the manufacturing process with 3D data. With previous versions of this solution, process procedure were represented by process names and parts images that can be assembled in processes, but they were insufficient for intuitive understanding of process layout, work procedures, and way of assembling.

The new version enables the creation of a more visual 3D-BOP solution that is suitable for the manufacturing site by means of graphics and insert images to indicate the arrangement of machines, worker flow lines, and work procedures on the process block diagram, displaying tools on snapshots and process shots (5), and easily creating shapes such as weld shapes, auxiliary materials, and jigs and tools. This reduces operational errors such as misuse of jigs and assembly work order, resulting in higher yield production.

2. VPS GP4, a manufacturing line process planning tool that improves work efficiency by centralizing data

With the previous versions of the VPS GP4 solution, which is used for examining the process plan of a manufacturing line with 3D data, it was necessary to create and edit design data on an individual basis, including for shared tasks. With this enhancement, it will be possible to mix common work and work with different specifications and express them in one data. As a result, when there is a change in a common operation, only one set of data needs to be corrected. This can reduce the operation time by up to about 70% (6). Moreover, since multiple operational procedures are represented by one set of data, it is easier to compare and examine each procedure. Thus, it is possible to apply reasonable improvement measures while looking at evaluation values of production lines.

Future Plans

Going forward, Fujitsu will continue to support Digital Transformation (DX) in the manufacturing industry, leveraging its capabilities as a leading technology company with extensive know-how in manufacturing and advanced technologies in fulfillment of its mission for its manufacturing brand, COLMINA: “Bringing innovation to manufacturing through the delivery of services that are global, open, and rapid that help to realize DX”

Sales Target

1,000 licenses by the end of fiscal 2021 (Fujitsu’s fiscal year ends at the end of March.).

(1) Fujitsu Manufacturing Industry Solution COLMINA Digital Production Preparation VPS:

Please note that outside the Japanese market the product is officially referred to as Fujitsu Manufacturing Industry Solution COLMINA Digital Manufacturing FJVPS.

(2) 3D Bill of Process:

Production preparation information that links data such as parts, work procedures, locations, equipment and tools, and manufacturing know-how used in product assembly with 3D data.

(3) Process block diagram:

A diagram that shows the relationship of the entire process and the flow of assembly work, including the positional relationship of workplaces.

(4) SDGs Action Plan 2021:

The Japanese government’s Headquarters for the Promotion of SDGs compiled specific measures for the promotion of SDGs in 2021.

(5) Snapshot or process shot:

A graphic representation of a scene of a manufacturing operation or process used as an illustration in a work instruction or process plan.

(6) Reduce the operation time by up to about 70%:

Confirmed by our sample model with 3 to 6 specification variations.

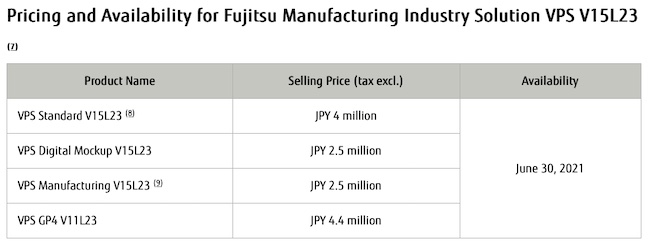

(7) Selling Price:

Network license price. Available to client terminals on the same network with unlimited installations. Up to the number of purchased licenses can be used simultaneously.

(8) VPS Standard V15L23:

A set of VPS Digital Mockup and VPS Manufacturing.

(9) VPS Manufacturing V15L23:

VPS Manufacturing requires a VPS Digital Mockup license.